Understanding DTF Adhesive Powder is key to achieving high-quality, long-lasting Direct-to-Film (DTF) prints on materials like textiles and ceramics. Premium adhesives offer enhanced bonding strength, color matching, and detail reproduction, preventing smudging and shifting during printing. Strategic considerations include using high-resolution design files, precise particle size control, and distribution techniques for crisp lines. Application methods like mist or brush coatings further enhance print quality, ensuring vibrant, professional outcomes.

Get ready to elevate your 3D printing game with this comprehensive guide on DTF (Direct-To-Final) printing and the secret ingredient—premium adhesive powder. Discover how this innovative material can transform your print output, ensuring superior adhesion and intricate details. Learn the science behind DTF printing, explore the benefits of high-quality adhesives, and unlock expert tips for achieving flawless results. Take control of your printing process and unlock the potential of DTF with this essential knowledge.

- Understanding DTF Print Output and Adhesive Powder

- The Role of Premium Adhesive Powder in Enhancing DTF Prints

- Tips for Achieving Better DTF Print Results with Adhesive Powder

Understanding DTF Print Output and Adhesive Powder

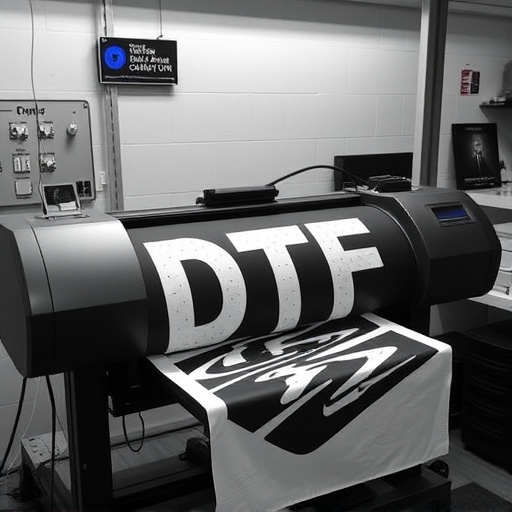

Understanding DTF Print Output and Adhesive Powder is key to achieving superior results in direct-to-film (DTF) transfer printing. DTF technology allows for high-quality reproduction of designs onto various materials, from textiles to ceramics. The process involves applying a thin layer of adhesive powder to a film, which then acts as a carrier for the design. This powdery substance plays a critical role in ensuring the image is accurately transferred to the desired substrate without smudging or imperfections.

Choosing the right DTF Adhesive Powder is essential for optimal print quality. Premium adhesives offer enhanced bonding strength and improved color matching capabilities, resulting in vibrant, long-lasting prints. The adhesive’s compatibility with different materials also matters; some powders are designed for specific substrates, ensuring a secure bond and precise detail reproduction. This precision is particularly crucial when aiming for intricate designs, as it directly impacts the final product’s visual appeal.

The Role of Premium Adhesive Powder in Enhancing DTF Prints

The quality of DTF (Direct to Garment) prints significantly improves with the use of premium adhesive powder, enhancing both the durability and aesthetics of the final product. Premium adhesives offer a crucial advantage by ensuring a strong bond between the design and the garment during the printing process. This is particularly important for intricate or detailed designs that require precise color reproduction and sharp lines. By providing superior adhesion, these powders prevent smudging or shifting of the print, resulting in more accurate and vibrant DTF transfers on various materials, including t-shirts, hoodies, and mugs.

Moreover, high-quality adhesive powders contribute to a smoother transfer process, which is essential for achieving professional-grade DTF heat transfers. Unlike regular adhesives, premium options are designed to withstand the heat and pressure applied during the pressing stage, ensuring the design is permanently fixed without leaving behind any residue or compromising the garment’s texture. This attention to detail is evident in the final output—dtf printed shirts, mugs, and other products turn out crisp, with colors that remain vibrant even after multiple washes, showcasing the superior performance of these specialized powders.

Tips for Achieving Better DTF Print Results with Adhesive Powder

Achieving exceptional results with DTF (Direct to Fabric) printing using adhesive powder requires a few strategic considerations. Firstly, ensure your design files meet the DTF design requirements, including high resolution and appropriate color profiles. Using vibrant designs can enhance the final print output significantly.

When working with DTF adhesive powder, it’s crucial to consider the transfer process by size. Precise control over the particle size of the powder is vital for effective adherence to fabric. Proper distribution and even coating of the powder on the design area will result in crisp lines and detailed prints. Experimenting with different application techniques, like using a fine mist or brush application, can also contribute to better print quality.

DTF (Direct-to-Film) printing has revolutionized the way we produce high-quality, precise prints. By utilizing premium adhesive powder, you can significantly enhance the output of your DTF prints. This article has explored the importance of adhesive powder in understanding and optimizing DTF printing processes. With the right techniques and tips shared, you’re now equipped to achieve better DTF print results by strategically using DTF Adhesive Powder.