DTF Adhesive Powder is a crucial component for achieving superior print adhesion on custom graphic tees and other textile products. It acts as a binding agent, creating an airtight seal between design and fabric with varying compositions suited for different materials, ink types, and print methods. In bulk DTF shirt production, it ensures long-lasting prints resistant to frequent washing. Proper preparation includes cleaning the substrate surface, selecting compatible high-quality powder, and evenly applying it for optimal print adhesion on hoodies and other fabrics using DTF printing processes.

Looking to boost the effectiveness of your print ads? Discover the power of DTF Adhesive Powder and unlock superior print adhesion. This guide breaks down the essentials, from understanding the basic principles of DTF adhesive powder to identifying key factors for maximizing adherence. Learn best practices to achieve optimal results and elevate your printing game.

- Understanding DTF Adhesive Powder Basics

- Key Factors for Effective Adhesion

- Best Practices for Optimal Results

Understanding DTF Adhesive Powder Basics

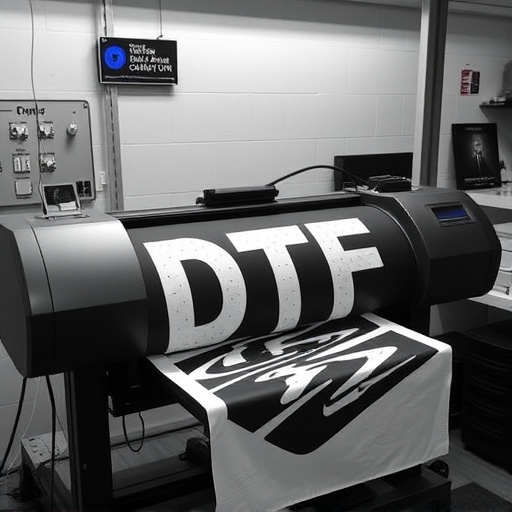

DTF (Direct to Garment) Adhesive Powder is a crucial component in achieving superior print adhesion for custom graphic tees and other textile products. Understanding its basics is essential for professionals in the garment printing industry. This powdery substance acts as a binding agent, creating an airtight seal between the design and the fabric. Its composition varies based on application requirements, offering options suitable for different materials, ink types, and print methods.

When used in bulk dft shirt production, DTF Adhesive Powder ensures long-lasting prints that withstand frequent washing. The process involves carefully applying a thin layer of powder to the target garment surface before transferring the design. This method is particularly popular among those who cater to high-volume orders, as it streamlines production while maintaining print quality. For example, when creating custom graphic tees, the right DTF adhesive powder can make all the difference in delivering vibrant, lasting designs that captivate customers.

Key Factors for Effective Adhesion

Achieving strong print adhesion on materials like hoodies using Direct-to-Film (DTF) printing is a science. Several key factors come into play when ensuring optimal bonding between ink and substrate, especially with DTF Adhesive Powder. Firstly, the surface preparation of the hoodie or any other fabric is paramount. A clean, dry, and grease-free surface allows for better contact between the adhesive and the material, enhancing overall adhesion.

The type and quality of DTF Adhesive Powder used play a significant role. Choosing an appropriate powder designed for DTF transfer printing ensures effective bonding. Additionally, factors like print resolution, ink type, and cure conditions must be optimized to create a strong bond. Getting these aspects right facilitates the creation of indelible, high-quality designs on personalized hoodies or other fabrics through DTF printing processes.

Best Practices for Optimal Results

To achieve optimal results with DTF (Direct to Film) adhesive powder, best practices include ensuring proper preparation of both the substrate and the powder. Start by cleaning the surface of the material thoroughly; any dirt or grease can interfere with adhesion. This involves using suitable cleaning agents and following recommended guidelines for your specific DTF printer and materials.

Next, choose a high-quality DTF adhesive powder that’s compatible with your direct to film printer and intended applications. Different printers and materials may require specific adhesives. Apply the powder evenly across the substrate using appropriate techniques, such as those provided by the manufacturer or industry standards for DTF transfer sheets. This ensures even coverage, enhancing overall print adhesion.

By understanding the fundamentals of DTF adhesive powder and implementing best practices, you can significantly enhance print adhesion. Key factors such as particle size, composition, and application technique play vital roles in achieving optimal results. Remember that choosing the right DTF adhesive powder is a game-changer, ensuring your prints stick firmly and last longer. Dive into these strategies to revolutionize your printing process and produce high-quality, durable materials.